Specialty chemicals and equipment for new energy refer to surface engineering specialty chemicals and dedicated production equipment required by the lithium batteries, photovoltaics, and other new energy industries, such as One-Step All-Wet Process of Composite Copper Foil Preparation Technology, Two-Step Process Composite Copper Foil Water Electroplating Equipment Technology, high-efficiency plating additive for monocrystalline heterojunction solar cells, etc.

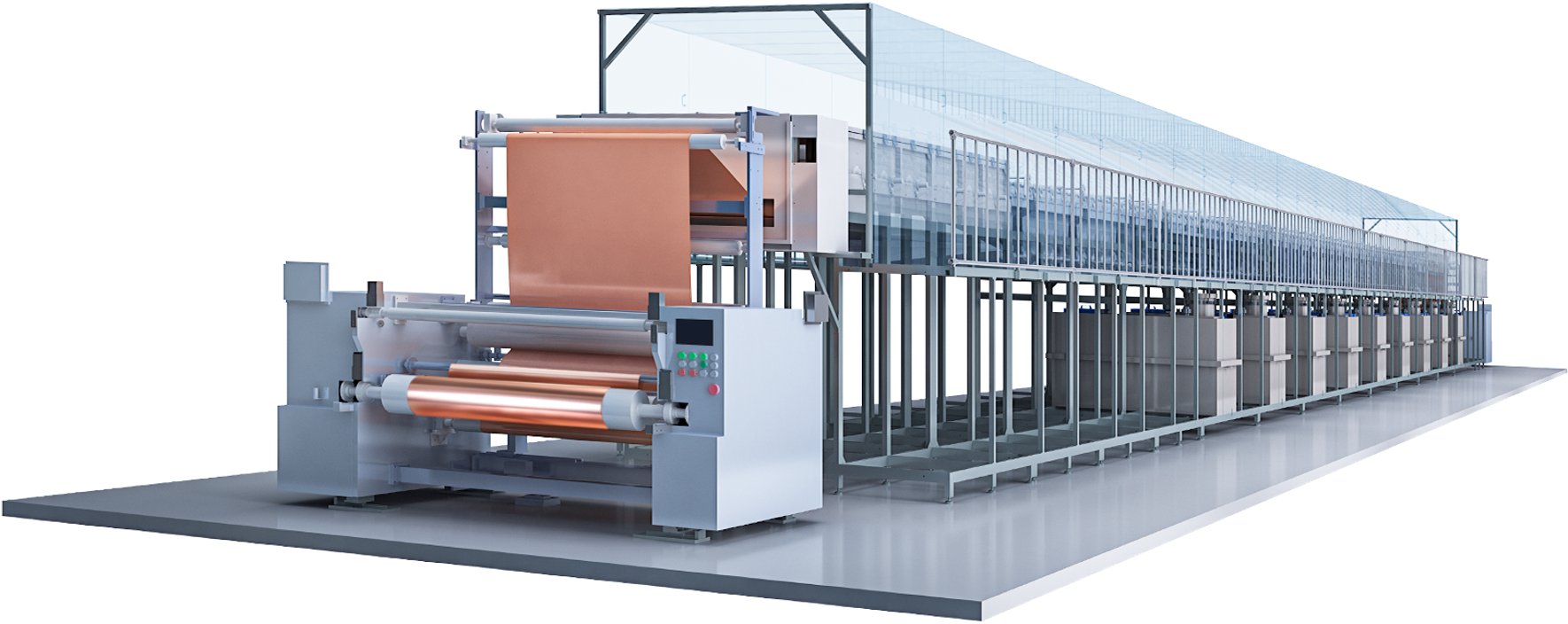

One-step all-wet Process of Composite Copper Foil Preparation Technology is used for the production and manufacturing composite copper foil, providing a ‘one-stop’ solution for specialty chemicals and equipment.

Sanfu replaces the ‘’two-step process’ with a one-step all-wet process, eliminating expensive equipment and raw materials, reducing process difficulty, lowering energy consumption, and ultimately improving product performance and reducing costs.

Adopting a horizontal design scheme, the film is treated by immersion in chemical solutions, with a pinch point-free design to avoid edge loss and film surface scratches caused by equipment; the film can maintain horizontal movement without excessive external force, avoiding single-point or local excessive force on the film, and with fewer winding and unwinding times during production, which is beneficial to avoid film deformation, tape breakage, and other abnormalities; the required operating temperature is low, effectively avoiding film perforation and other abnormalities. In addition, the equipment design also considers the simplicity of operation and the convenience of maintenance.

Product Advantages:

1. Completed with one process only, saving energy and manpower caused by multiple processes during transit;

2. No edge trimming, excellent adhesion, more uniform coating, higher yield rate;

3. Simple to operate, automatic winding and unwinding, easy to maintain;

4. Effectively reduces the number of winding and unwinding times to avoid film deformation;

5. Suitable for large-width film production

1. Yield rate over 95%: using new cathode roll to roll conductive technology

(1) Pinch point-free design, no edge trimming required, yield rate improved by approximately 6-10%;

(2) Avoid film breakage and wrinkles, improve coating uniformity;

(3) Convenient operation, automatic winding and unwinding.

2. Large width: 1650mm large-width advanced process

(1) The market width is 1200~1350mm, our company can support 1650mm large-width film production;

(2) can increase the production capacity of composite copper foil by 30%.

3. High production speed: production speed up to 10m-15m/min

(1) The market production speed is around 3-7m/min, and our 1650 mm large-width equipment production speed reaches 15m/min;

(2) can significantly improve production efficiency and achieve increased efficiency in the composite copper foil production.

High-efficiency plating process for monocrystalline heterojunction solar cells is used for the manufacturing of high conductivity pure copper grid lines and high solderability pure tin coatings in heterojunction solar cells. High-efficiency plating process for monocrystalline heterojunction solar cells is one of the best alternatives to traditional screen printing silver paste processes. As its core raw material, high-efficiency plating additives for monocrystalline heterojunction solar cells have broad application space.

The high-efficiency plating process for monocrystalline heterojunction solar cells has the following advantages:

(1) Produced under ‘near room temperature’ conditions without damaging silicon wafers, thin films, and oxide films;

(2) Achieve ‘copper instead of silver’, reduce electrode material costs by nearly 70%;

(3) Increase conductivity by more than 4 times;

(4) Perform double-sided plating simultaneously, with high production efficiency;

(5) Effectively increase the light receiving area;

(6) Can be combined with standard, welding based component interconnect technology.

Product Advantages:

(1) The plating solution has excellent dispersion and depth capabilities, and can maintain long-term stability and clarity;

(2) A pure copper coating with uniform appearance, excellent conductivity, extremely low stress, excellent ductility, and outstanding adhesion can be obtained, achieving ‘copper instead of silver’, reducing electrode material costs by nearly 70%, and increasing conductivity for more than 4 times;

(3) Can be used at near room temperature conditions of 24-37℃ without damaging silicon wafers, thin films, and oxides, and without affecting the function of heterojunction battery cell products and component products, helping to reduce material costs and significantly save energy consumption.